IOT solves problems in the manufacturing process.

At a manufacturing site, where a variety of equipment is in operation and many people are working, there may appear to be no problems at all, but in fact there are many hidden "wastes" and "risks" that pose a variety of challenges.

Sakae proposes a variety of IOT solutions that match the customer's site by utilizing the production site know-how that we have cultivated over the years.

The PDCA cycle, which collects and utilizes equipment data to solve problems such as quality improvement and cost reduction, leads to results that defy conventional wisdom.

Monitoring of production

By monitoring whether the production equipment in the factory is operating properly, it is possible to continue stable production activities and highlight issues during production that were difficult to see.

Do you have any of these problems?

・Equipment is of different makes and years, and operation management is done by hand, which is time-consuming and labor-intensive.

・Since the information is written by a person, there are many omissions and omissions.

・No detailed analysis of facility operating hours, etc.

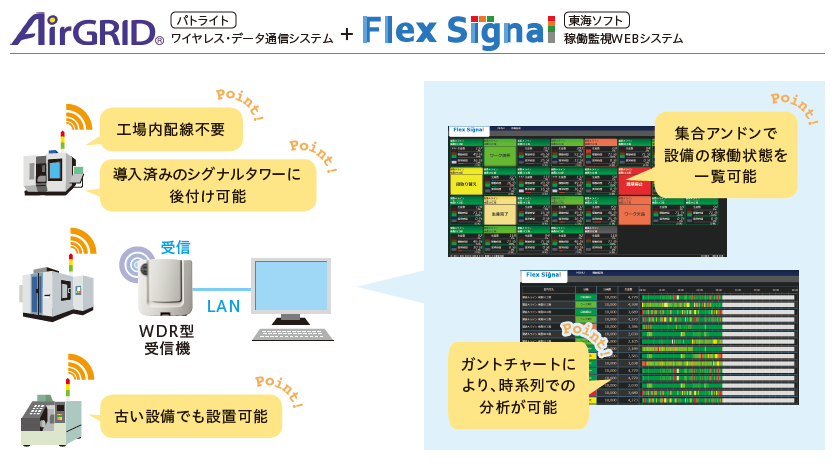

Wireless collection of "equipment operating information" with Patlite's AirGRID + Tokai Soft's Flex Signal and display of "operating loss" in chronological order will enable analysis of equipment operating information.

Predictive maintenance

By monitoring the condition of their equipment and identifying trends, they can prevent sudden responses in advance and keep their equipment running in a planned manner.

Do you have any of these problems?

・Wiring is difficult due to equipment scattered throughout the layout

・Difficult to achieve because of the considerable cost of construction.

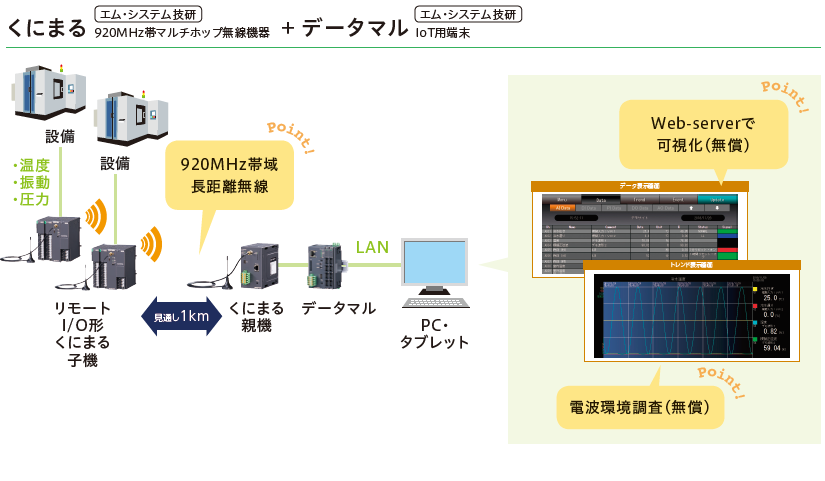

kunimaru+ datamaru by M System Giken enables predictive maintenance that collects and monitors data wirelessly.

Work improvement and technology transfer through the application of video

By capturing video of the work, analyzing and improving it, work time can be reduced by improving work efficiency, and the skills of skilled workers can be passed on to the next generation.

Do you have any of these problems?

・Difficult to get others to understand with words

・Skilled workers have retired and it is difficult to pass on skills.

・Different people produce different quantities per day, even though they are performing the same tasks.

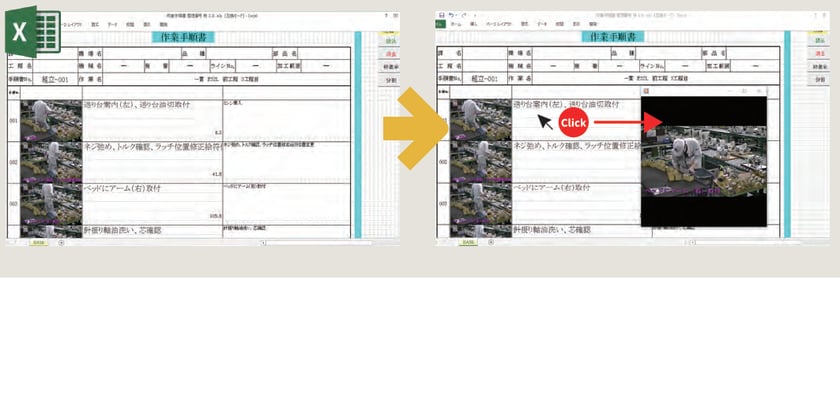

PEGASUS CO., LTD.'s DPA is a software that can materialize technology by promoting visualization, such as "handing down technology (training newcomers)," "operation analysis," "work improvement," and "process standardization" through the use of video. DPA can solve issues such as technology transfer and work time reduction.